Lightweight construction

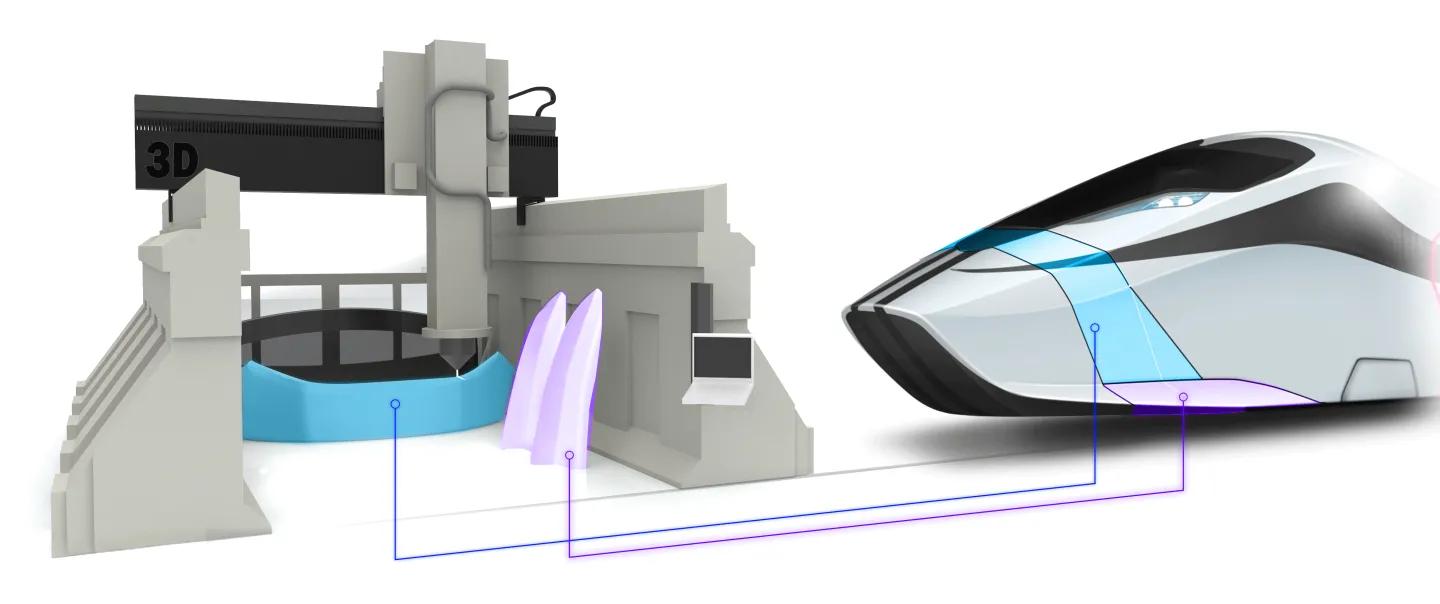

3D-FiberTrain

Entwicklung eines werkzeuglosen Fertigungsverfahrens zur Herstellung großformatiger und hochbelastbarer Schienenfahrzeugkomponenten

Projektzeitraum: Sep 2023- Jun 2026 | Projektpartner: Fraunhofer IWU, Lakowa Kunststoffbe- und verarbeitungs GmbH, Siemens Mobility GmbH (assoziiert)

Das Forschungskonsortium um HÖRMANN Vehicle Engineering erforscht und entwickelt eine innovative thermoplastische Technologie, die Großformat-3D-Druck mit dem 3D-Tape-Legeprozess kombiniert. Diese Methode ermöglicht die werkzeugfreie Herstellung komplexer und belastbarer Großkomponenten für Schienenfahrzeuge, wie Frontmasken und Dachstrukturen. Besonders bei kleinen bis mittleren Seriengrößen bieten additive thermoplastische Verfahren erhebliche Optimierungspotentiale in Kosten, Zeit und Material sowie eine Reduzierung des CO2-Fußabdrucks. Der Verzicht auf Formwerkzeuge, hoher Automatisierungsgrad und der Einsatz wiederverwendbarer Materialien führen zu niedrigeren Herstellungskosten und verbesserter Ressourceneffizienz im Vergleich zu herkömmlichen duroplastischen Faserverbundverfahren.

Gefördert durch: