RAMS and LCC

Efficiency for your technical product

The RAMS management - normatively anchored in the development by the EN 61508, EN 50126, ISO 26262 etc. - supports the development process with regard to reliability, availability, maintainability and especially safety (RAMS).

The implementation of the processes, which are not least relevant for approval, influences the development through the applied methods so positively that the product quality is increased and time and costs are optimized.

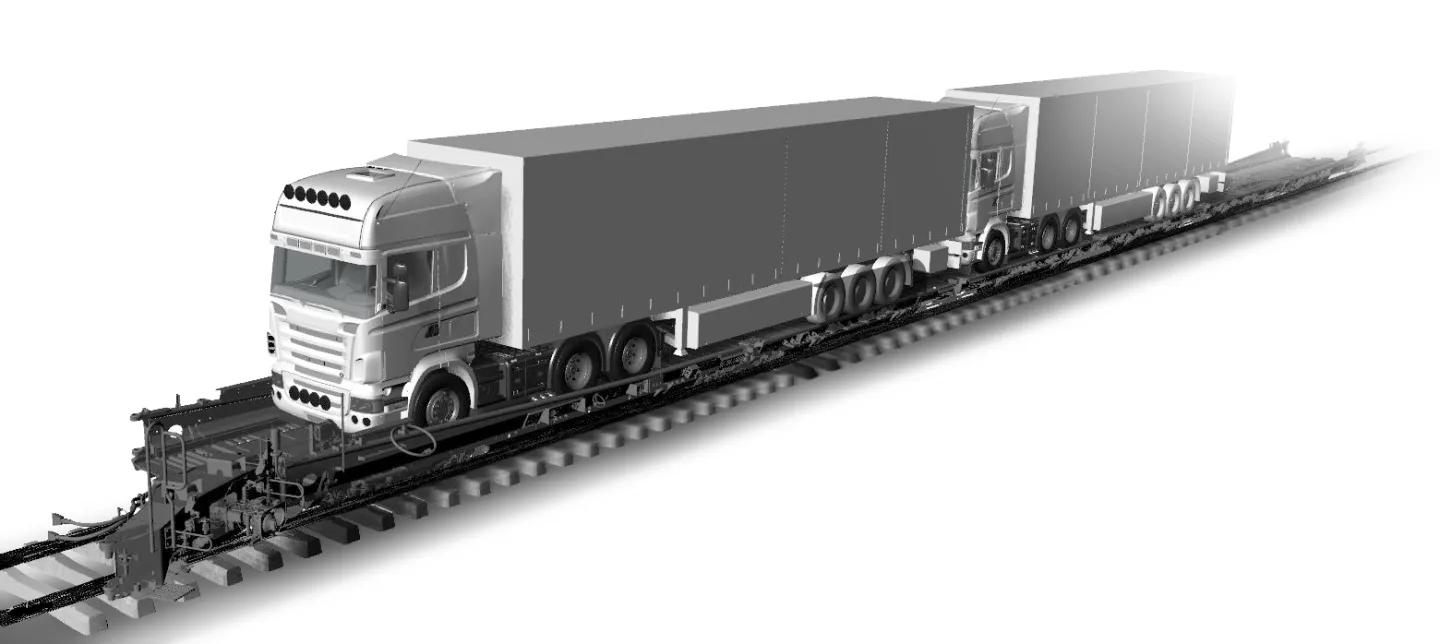

"Life Cycle Costing" is a proven means to commercially evaluate especially high capital goods with long life cycles. In the field of vehicle development, especially rail vehicle development, these analyses are used by end customers as a universal basis for product comparison.

Furthermore, we apply methods such as "target costing" in the development process in order to sound out the economic optimum between development, production and operation of the products

- Safety management: danger and risk analysis, design of safety architectures, maintenance of proof of safety according to EN 50129 or CSM (Common Safety Methods) according to EU 402/2013

- RAM analysis for improved reliability, availability and maintainability using RAM analysis, FMECAs, FTAs and proof of availability requirements

- Creation of maintenance concepts, plans and instructions as well as the operating manual

- Implementation of life cycle costing analyses (LCC)