References Rail Vehicles

With more than 30 years of experience in the rail vehicle sector, HÖRMANN Vehicle Engineering has successfully supported numerous international customers with its complete vehicle competence and/or as an engineering partner. Get an overview of our rail vehicle references: from streetcars, metros, EMUs and high-speed trains to locomotives and special vehicles.

TRSC - Low-floor tram for New Taipei City

The Taiwanese manufacturer Taiwan Rolling Stock Company commissioned HÖRMANN Vehicle Engineering with the complete development of the new low-floor tram for New Taipei City. Thanks to our concepts, TRSC was able to win the contract in a tendering competition.

- Project Management

- Conception

- Industrial Design

- Mechanical and Electrical Development

- Vehicle Control

- Calculation and Simulation

- RAMS and LCC

- Factory and Production Planning

- Test and Commissioning

SLRVE - Low-floor tram for Shenyang

For the Chinese rail vehicle manufacturer Shenyang Liyuan Railway Vehicle Equipment Co. (SLRVE) in Shenyang, HÖRMANN Vehicle Engineering developed a modern 100 percent low-floor tram. The HÖRMANN company was responsible for the complete vehicle development, from project management, conception, industrial design, the entire mechanical and electrical engineering services, calculation, RAMS and LCC.

As SLRVE equipped its workshop with the latest production technologies parallel to the development of the vehicle, we were able to use the entire range of state-of-the-art workshop equipment and to tap into savings potential in terms of production time and costs.

- Project Management

- Conception

- Industrial Design

- Mechanical and Electrical Development

- Vehicle Control

- Calculation and Simulation

- RAMS and LCC

CRRC Changchun - Low-floor tram for Shenyang

HÖRMANN Vehicle Engineering developed China's first low-floor tram for CNR Changchun. 20 trams have been in operation in Shenyang since 2014.

The special features of this project included built-in underfloor panel heating and an extremely large (raised) panorama window, as well as newly developed LED lights in the front area. With an ambitious schedule, the first low-floor tram was ready in time for the China National Games 2013.

- Project Management

- Conception

- Industrial Design

- Mechanical Development

- Calculation and Simulation

- RAMS and LCC

- Test and Commissioning

Solaris – Leipzig XL

The Polish tram manufacturer Solaris commissioned HÖRMANN Vehicle Engineering to develop the body shell of the new Leipzig tram. The project was the second for Solaris after the bodyshell development for the first Solaris tram in Poznań.

- Conception

- Mechanical Development

- Calculation and Simulation

- Test and Commissioning

Heiterblick - tram VAMOS Dortmund DWS21

For Heiterblick, HÖRMANN Vehicle Engineering is planning and designing the new and modernization vehicles based on the existing fleet of B80 cars in Dortmund.

Special challenges are the transfer of an existing vehicle concept and a given vehicle structure into a new, independent vehicle development. The light rail vehicles will be provided with improved passenger comfort by ventilation as required, larger multifunctional areas and by the method of raising and lowering the vehicles on the platform, which is used for the first time in light rail vehicles.

Against the background of a comfort-related increase in unladen weight and higher payloads, compliance with the permissible gross vehicle weight and permissible axle loads is also being realized.

- Project Management

- Conception

- Mechanical Development

- Integration of the Electrical Development

- Calculation and Simulation

- RAMS and LCC

- Test and Commissioning

Heiterblick | Vossloh Kiepe | Alstom – TW3000 tram Üstra Hannover

For the Leipzig tramway manufacturer Heiterblick, HÖRMANN Vehicle Engineering developed the new high-floor tram for the Üstra in Hanover. In addition to the complete mechanical development, the service also included bogie development for Alstom.

- Conception

- Mechanical Development

- Calculation and Simulation

Beijing Rail Transit Technology and Equipment Group RTTE – 160km/h Inter-City-Train

RTTE commissioned HÖRMANN Vehicle Engineering with the development of a multi-system intercity train for a maximum speed of 160 km/h for metro and mass transit operations in the greater Beijing area. The design services covered the complete spectrum from the body shell, interior, exterior, mechanical and functional electrics to on-site support in production.

- Project Management

- Conception

- Industrial Design

- Mechanical and Electrical Development

- Vehicle Control

- Calculation and Simulation

- RAMS and LCC

- Factory and Production Panning

- Test and Commissioning

CRRC ZELC - Double-decker high-speed train in China

CRRC in Zhuzhou commissioned HÖRMANN Vehicle Engineering to develop a double-deck train in aluminium and steel construction for 200 km/h and a single-deck train in aluminium construction for 250 km/h. The double-decker train in aluminium has already been completed as a prototype. The special feature is the lightweight construction with the compliance of 17t axle load.

- Project Management

- Conception

- Industrial Design

- Mechanical Development

- Vehicle Control

- Calculation and Simulation

Bombardier – Dosto 2010

On behalf of Bombardier Görlitz, HÖRMANN Vehicle Engineering developed different complete variants of the double-deck control cars and center cars. The first 3 vehicles for DB Fernverkehr were first shown at InnoTrans 2014. A total of over 600 vehicles of this platform have been manufactured and delivered to date.

- Project Management

- Conception

- Industrial Design

- Mechanical Development

- Vehicle Control

- Calculation and Simulation

Bombardier – Zefiro 380 high-speed train

With around 100 engineers, HÖRMANN Vehicle Engineering worked on the development of the Zefiro, designed for 420 km/h, for Bombardier in Hennigsdorf between 2009 and 2011. We took over the complete mechanical engineering services for the bodyshell and interior design including the extensive calculations and simulations. A further service point was the industrial design, which was carried out in cooperation with the agency Tricon.

- Industrial Design

- Mechanical Development

- Calculation and Simulation

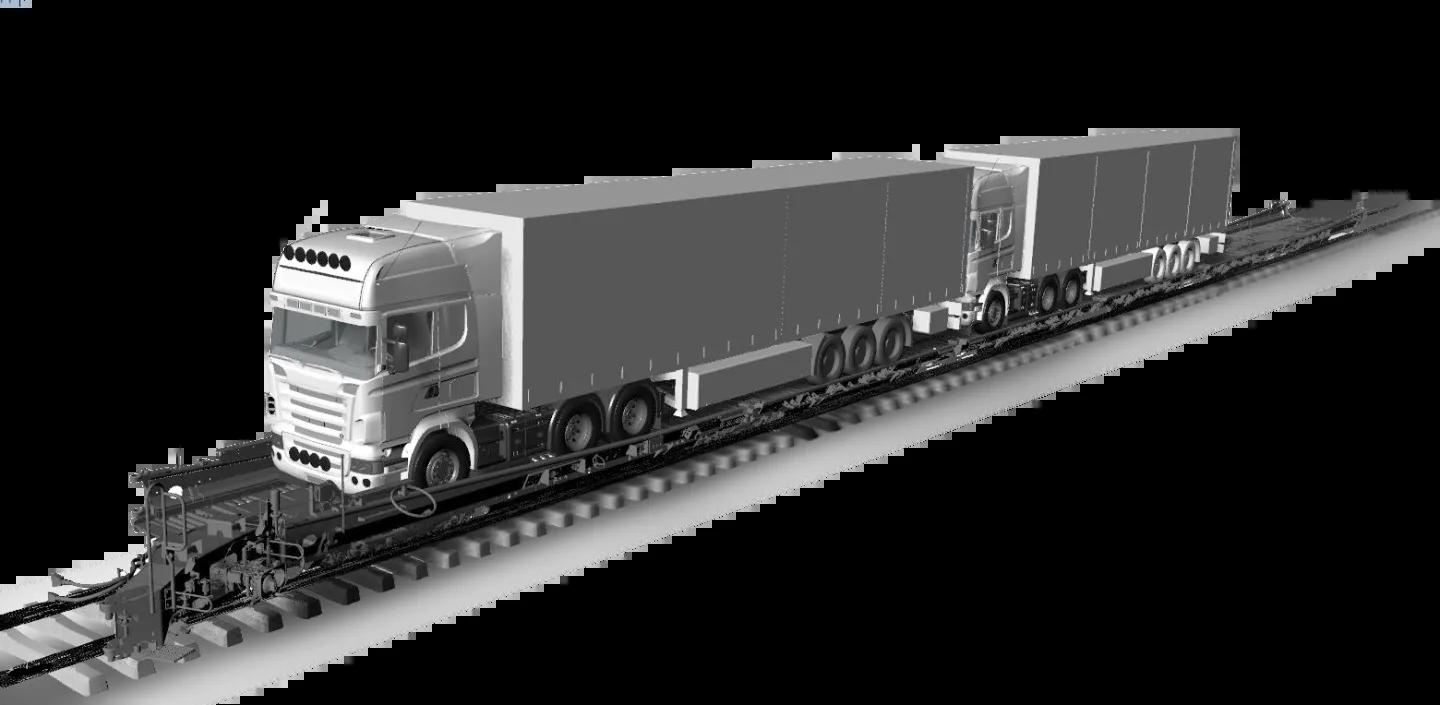

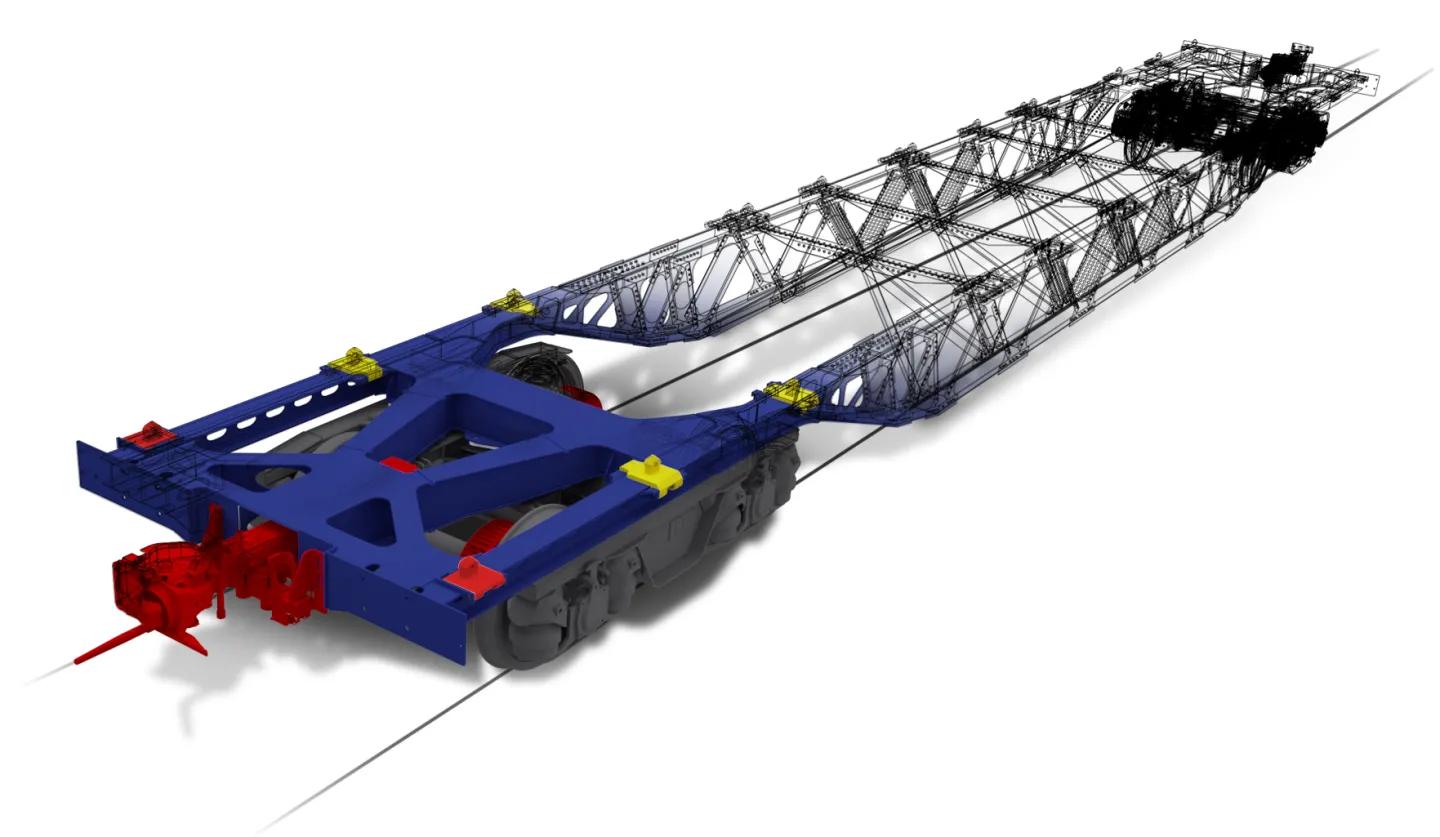

RAlpin – innovative RoLa articulated train

HÖRMANN Vehicle Engineering developed an innovative rolling stock for RAlpin AG, the Swiss operator of the Rolling Road (RoLa). The new rolling stock for the RoMo 2020 is an articulated train for accompanied combined traffic for the transport of entire trucks. The articulated train is to operate mainly in the European area (CH, A, D, IT) and be approved according to the TSI-WAG standard. A main difference of the innovative RoLa articulated train compared to the existing low-floor carrying wagons is that the trucks can be transported across wagons at a distance of 300mm.

SBB Cargo – Lightweight support frame

The task of HÖRMANN Vehicle Engineering was to develop a chassis that combines the attributes of lightweight construction, economical production, a high degree of automation in the manufacturing processes, use of standard parts, and reduction of the welding effort. The modular chassis consists of 3 parts and offers flexible use for various transport tasks and superstructures with higher payloads.

FLC – Locomotive 2EV120 in Russia

For the Russian First Locomotive Company based in Engels on the Volga, the cabin of the 2EV120 electric multi-system locomotive (on the Bombardier TRAXX platform) was developed. HÖRMANN Vehicle Engineering manufactured and commissioned this for the first 4 units.

We manufactured a 1:1 mock-up to investigate the ergonomics and to obtain the necessary certifications in Russia.

Alstom – H3 locomotive

HÖRMANN Vehicle Engineering developed the concept of a new type of hybrid locomotive for Alstom. A very economical and environmentally friendly diesel generator charges the battery and can also drive the electric motor directly for peak loads. At partial load, the locomotive runs on battery power, thus saving 30 to 50 percent diesel in this version compared to conventional 700kW shunting locomotives. This platform concept can also be used to implement 3 additional drive solutions (dual engine / battery / DE-1000kW).

Harsco – Special vehicles

HÖRMANN Vehicle Engineering designed the concept development for the Norwegian state railroad:

- Maintenance Vehicles

- Tanker Vehicle

- Fire-Fighting Rescue Vehicle

- Measuring Vehicle

Our services consisted of the design of a platform for diesel-hydraulic and diesel-electric drive variants of the vehicles, the mechanical arrangement of all components in the vehicles, the integration of crew cabins and work areas as well as in weight management and the preparation of the vehicle descriptions.

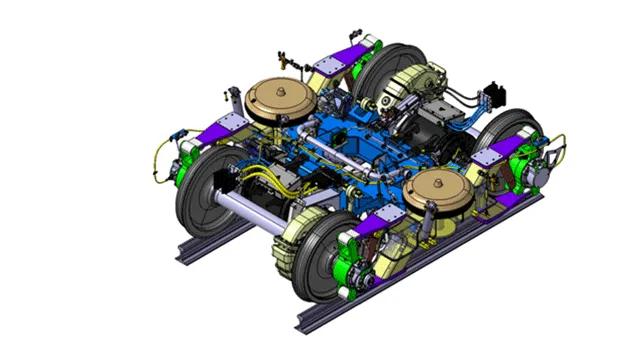

TRSC – Bogie for New Taipei City low-floor tram

For the Danhai LRT project of the Taiwanese rail vehicle manufacturer Taiwan Rolling Stock Co., HÖRMANN Vehicle Engineering developed special motor and running gear with cranked axles for New Taipei City. Special performance requirements had to be met for inclination and acceleration, while adhering to the maximum permissible axle load.

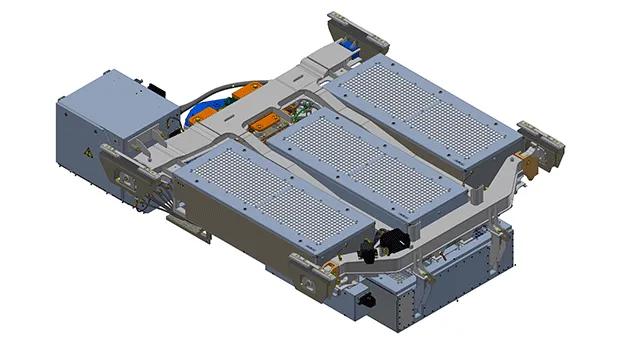

ABB – Drive module for EcoTrain

HÖRMANN Vehicle Engineering was responsible for the project planning, development and design of a hybrid drive module, which is equipped with a diesel engine-generator unit, a traction motor-transmission unit and cooling systems. This hybrid drive module is used in the EcoTrain, which was converted on the basis of a VT-642. For the prototype of the Ecotrain, we manufactured a hybrid drive module and carried out the electrical and mechanical functional testing.

ABB – Power module for EcoTrain

HÖRMANN Vehicle Engineering was responsible for the project planning, development and design of a hybrid energy module, which is equipped with several battery units, a central transfer box and a traction motor-transmission unit. This hybrid energy module is used in the EcoTrain, which was converted on the basis of a VT-642. For the prototype of the Ecotrain, we produced a hybrid energy module.